This project consisted of designing, prototyping, and implementing a 3 axis positioner for a silicon diffraction crystal in the BMIT beamline at the Canadian Light Source.

Background

Diffraction enhanced imaging is an X-ray imaging technique where a silicon crystal with a particular lattice structure called an analyzer crystal is placed between the sample and camera. The X-ray diffracts through the crystal lattice structure as defined by Bragg’s Law. Slight changes in the angle of the analyzer significantly effect the contrast of the image, allowing much higher contrast than normally achievable.

We had a set of PI Nexline Actuators sitting around, and thought they would be a good use for building an analyzer positioner due to their extremely small minimum incremental move capability.

Design

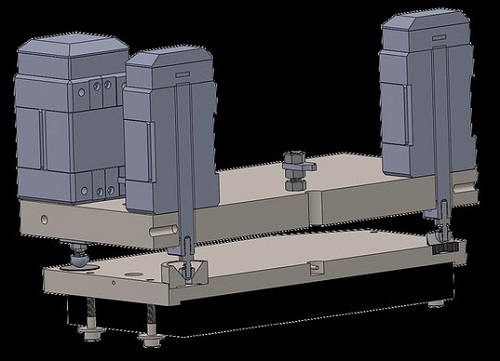

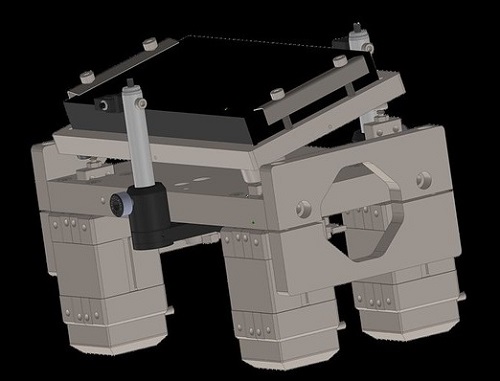

Overall the design is pretty straightforward. Two flat plates, the moveable one mounted on kinematic compoments. Cone/vee/plane kinematic elements were chosen instead of the typical 3 vee configuration to simplify things by having a defined point of rotation about the cone. The kinematic contacts were preloaded with springs.

A pair of sheet metal springs was originally designed to hold in the crystal without deforming it. This was later swapped for dimpled washers as we could make them easily.

Assembly

A proof of concept prototype was built from a pair of acrylic plates prior to ordering machined parts. It worked great! Repeatability was somewhat verified with a laser pointer and a long hallway.

The analyzer positioner proof of concept

The analyzer positioner proof of concept

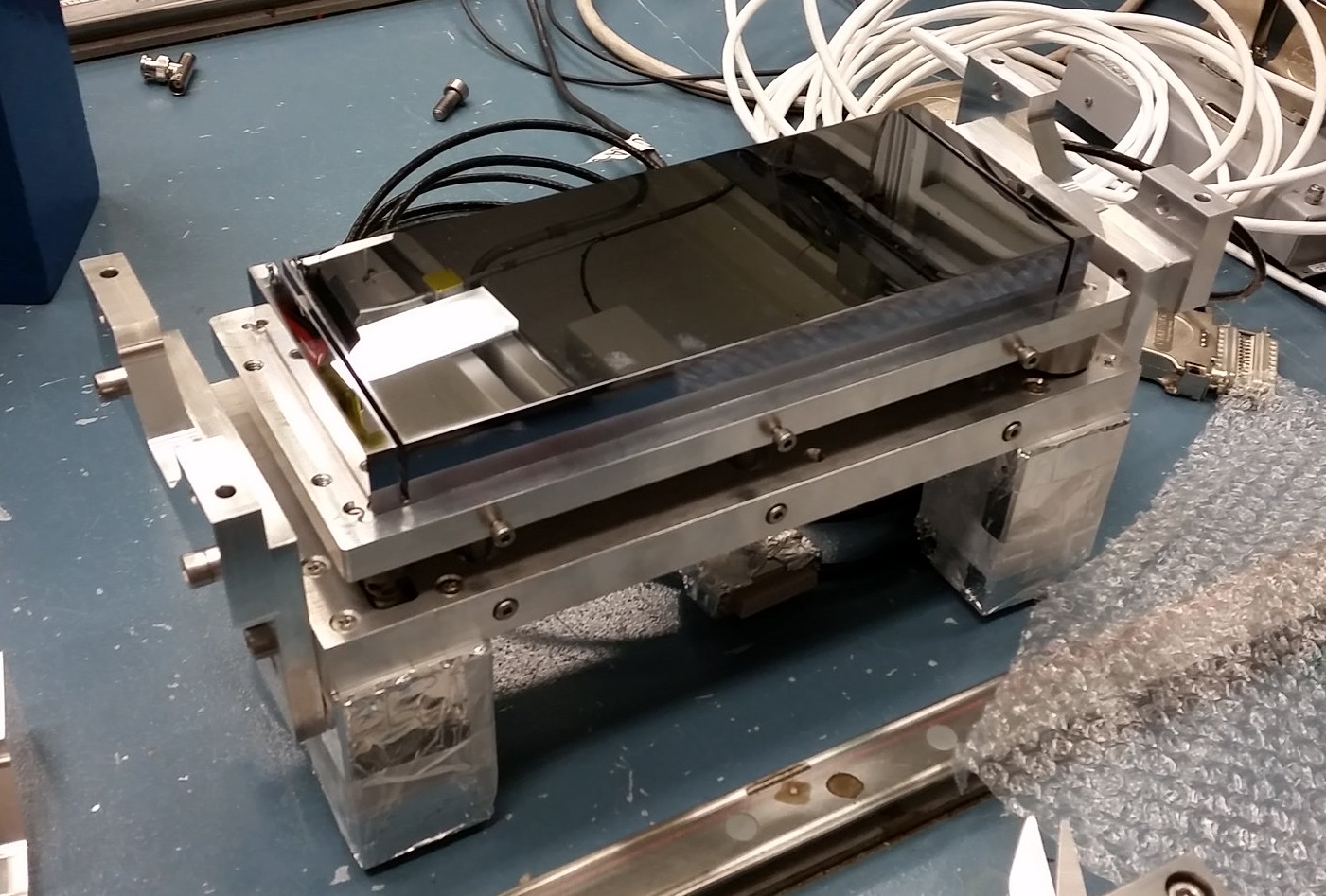

The final machined version also went together surprisingly well. Extreme care had to be taken because the silicon crystals are fragile and nearly priceless.

The final analyzer positioner prior to installing in the beamline

The final analyzer positioner prior to installing in the beamline

Installation

Installation was also a very delicate procedure because the whole assembly needed to be inverted. There was a moment of truth seeing if the springs were strong enough to keep the kinematic elements preloaded with the weight of the crystal.

The analyzer positioner installed in the beamline

The analyzer positioner installed in the beamline

It worked! The system actually worked very well due to the fine resolution and high repeatability of the piezo actuators. Stability of the system was also excellent; the beam would still be aligned after leaving it for 24 hours.

The first time we got the beam aligned. You can see how the aluminum parts block the X-ray.

The first time we got the beam aligned. You can see how the aluminum parts block the X-ray.